Europe Bizerba releases xray food inspection system Food News International

Food Safety Magazine reports that in 2017, there were no fewer than 42 large-scale recalls prompted by foreign contaminants. Many of these costly events could be avoided with the use of evolving X-ray technology. Let's look at three ways X-ray inspection systems are changing the food industry for the better. 1.

Bakery Xray Inspection Systems Sapphire Inspection

An x-ray food inspection system consists of one or more x-ray generators, an x-ray image camera (detector), a cabinet or casing that contains radiation emissions, and a computer control system. Systems work by sending x-rays through products to create x-ray images. The resulting images are inspected manually or automatically, and then compared.

A Guide to Different Types of XRay Food Inspection Systems

Service contracts should form part of any x-ray system purchase. Regular servicing of an x-ray system, including performance verification, will ensure it is operating at the optimum level of performance. This will prevent food safety issues. Preventative maintenance enables manufacturers to avoid downtime issues due to unexpected maintenance work.

A Guide to Different Types of XRay Food Inspection Systems

The benefits of X-ray inspection in detail Our X-ray food inspection systems detect contaminants such as metals, glass, ceramic, stones, bone fragments, PVC, Teflon, rubber and glass-fibre-reinforced plastics in food products such as packaged meat, pastas, and ready-made meals; Detect contaminants as small as 0.3 mm in particle size

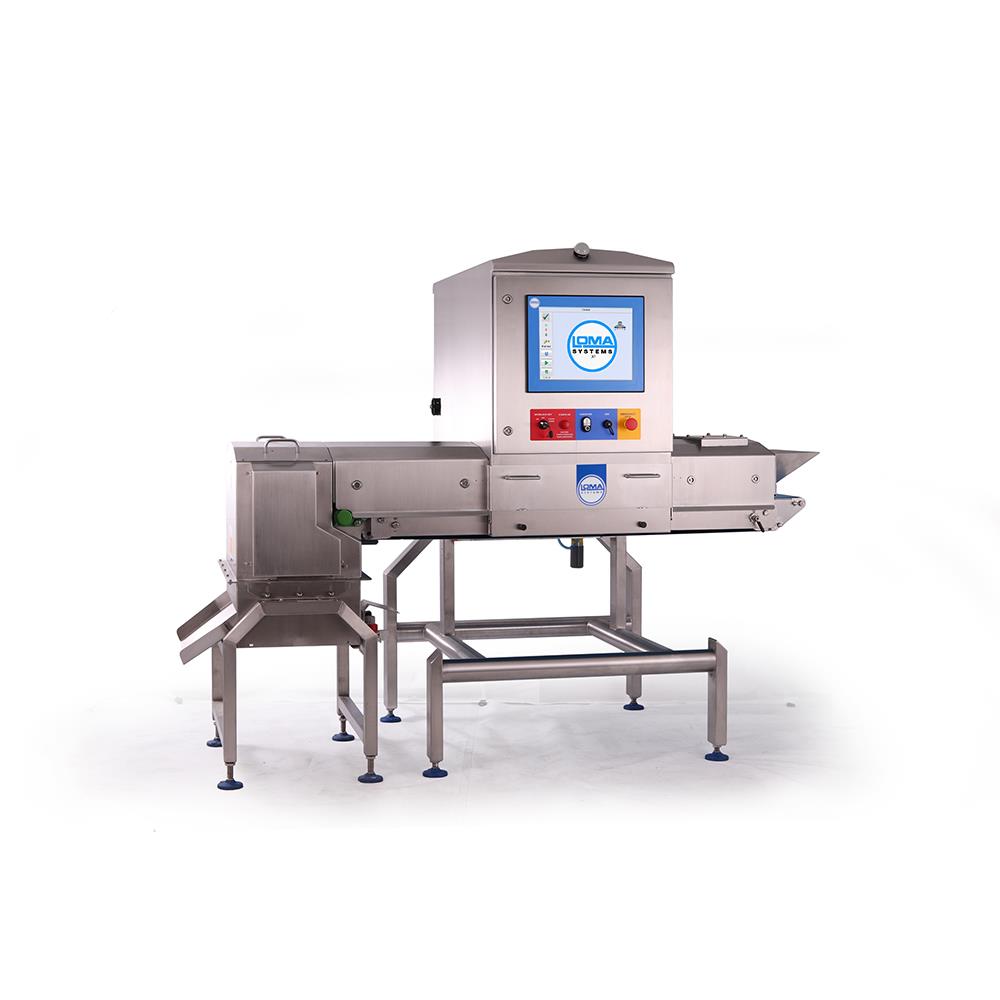

Food Xray inspection Systems Loma Systems

FlexXray's advanced, medical-grade X-ray systems can detect metal, glass particles, stone, bone, plastic, rubber gasket material, product clumps, container defects, wood and missing components 0.8 mm and smaller. This state-of-the-art equipment exceeds standards for food inspection machines found in food production plants.

Used Sesotec Raycon XRay Food Inspection System

An x-ray inspection machine for the food industry is a sophisticated system used to detect physical contaminants in food products. Our advanced x-ray inspection machines can reliably and quickly inspect food packaged in plastic containers, foil pouches, glass jars, and metal cans, as well as loose and pumped products, such as meat and poultry.

Iris Pipeline X ray Inspection System Sparc Food Productions System

Food x-ray systems work using a process called radiographing to check for contaminants and inadequacies in a food product. The process involves the following steps:. X-ray technology and food inspection systems are constantly improving. Such advancements make it possible to safely scan a wide variety of food products for contaminants with.

Medusa X Ray Food Inspection Machine Sparc Systems

X-RAY INSPECTION. X-ray detection is a fast-growing inspection method used within food production factories and provides improved safety and brand protection. Operating under LOMA's core "Designed to Survive" philosophy, our engineering teams provide solutions built around the following key values for X-ray inspection systems in the food.

Food X Ray Inspection System with Auto Rejection, एक्स रे इंस्पेक्शन सिस्टम, एक्स रे निरीक्षण

Industrial x ray food inspection systems manage risk & improve quality by finding foreign objects & detecting product defects before they reach consumers.. IX-EN Series X-ray Inspection System Enhance quality control on your production line, both affordably and effectively, thanks to Ishida's Genetic Algorithm (GA) image processing and 5.

Foodman Food XRay Inspection System for Unpackaged Bulk Products Easyweigh

Any time you suspect you have a contamination issue with your processed food, we offer inspection services that can be performed quickly at any of our four locations throughout the U.S. We also offer single camera X-ray machines and metal detectors for rent if you want to inspect your product on your own at your facility.

XRay Inspection Systems for Food Industry Mekitec

TDI Packsys offers food x-ray inspection systems in dozens of sizes across various distinct series, providing custom solutions for each specific application. Our focus is always on constantly improving our technology, enabling us to continue leading the industry in performance and sensitivity. Interchangeable generators, upgraded software.

Use of Xray Inspection Systems in the Food Industry Quality Assurance

Since the production and processing of food of course is a highly sensitive field, the European Union has passed a specific directive 1999/2+3EG concerning the use of inspection systems on X-ray basis to guarantee 100 % safety of the inspected products:

XRay Food Inspection Equipment From AccuWeigh Industry Update Manufacturing Media

As such X-ray inspection systems may help reduce inspection costs for some food businesses. 2 Disadvantages of x-ray inspection X-ray inspection has a number of distinct disadvantages including its relatively high cost and the need for high voltage power supplies to generate X-rays. 2 X-ray inspection also has a number of perceived.

Used Sesotec Raycon XRay Food Inspection System

X-ray scanning offers the food processing industry excellent versatility and functionality in food inspection. X-ray inspection systems can detect a wide variety of metallic and non-metallic contaminants, but also deliver additional quality control capabilities, including the detection of missing product pieces and components, under- and over.

Food Xray inspection Systems Loma Systems

X-RAY INSPECTION. X-ray detection is a fast-growing inspection method used within food production factories and provides improved safety and brand protection. Operating under LOMA's core "Designed to Survive" philosophy, our engineering teams provide solutions built around the following key values for X-ray inspection systems in the food.

Medusa X Ray Food Inspection Machine Sparc Systems

By their very nature, X-ray systems used for food inspection are safe and emissions are significantly less than many naturally occurring radiation sources such as medical X-rays, Radon gas, Gamma decay in rocks, cosmic rays and even the Sun. The world's average "background" rate of radiation is around 2.7 mSv/yr. Working a 40 hour week.