How To 3D Print Gears Like A Pro 7 Design Tips and Advice

Very high efficiency for 3D printed gears made of high-performance polymer Planetary gearbox efficiency testing showed that gears laser sintered from iglidur i3 had efficiency in dry operation comparable to that of oil-lubricated metallic planetary gearboxes.How can that be? The solid lubricants contained in iglidur polymers greatly reduce the coefficient of friction so that dry-operating 3D.

3d Printed Electronical Gear Ratio 3 Steps Instructables

1. Polycarbonate 2. Nylon 3. PLA 4. PEEK How Do You Make 3D Printed Gears Stronger? Calibrate Your Printer Print the Gear Face Down Calibrate the Printing Temperature Adjust Infill Settings 3D Print Gears with Fewer Teeth How Do You Lubricate PLA Gears? Can You 3D Print a Worm Gear? Can You Resin 3D Print Gears? Are 3D Printed Gears Strong Enough?

3D printed gears pro design tips and software advice Sculpteo Blog

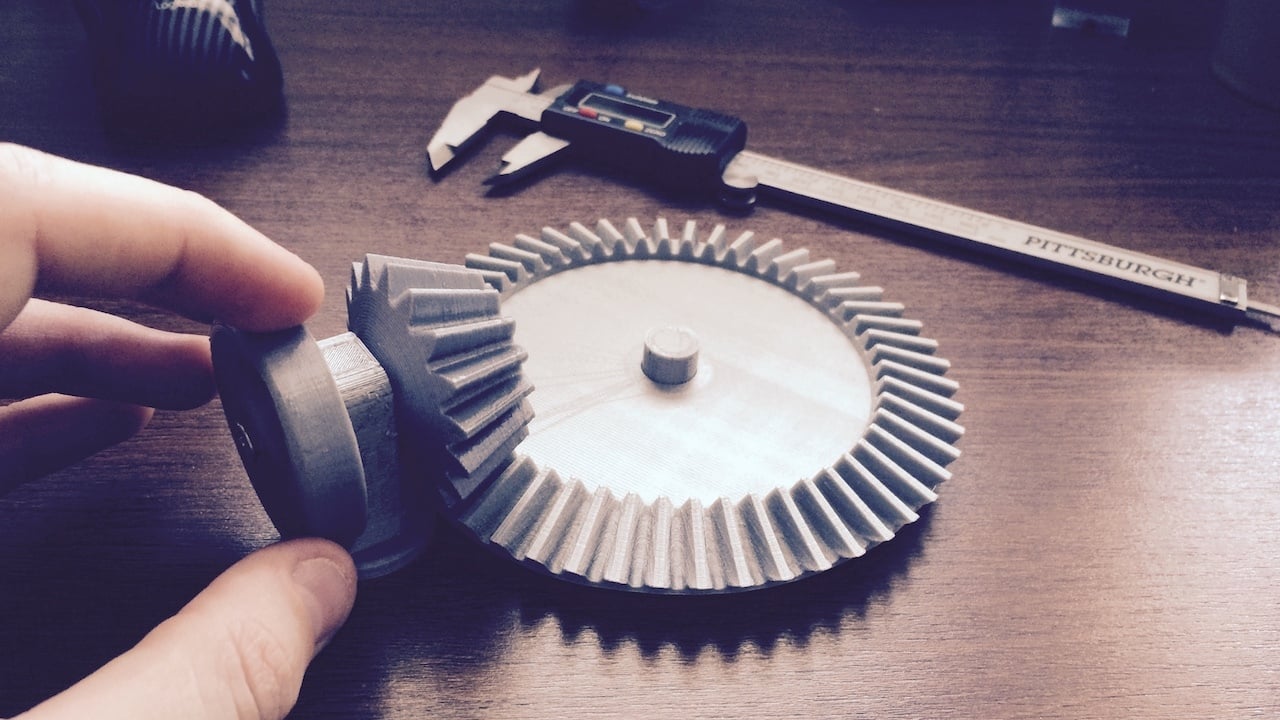

February 10, 2022 When it comes to making gearboxes, 3D printing has the benefit that it lets you whip up whatever strange gears you might need without a whole lot of hunting around at.

morská riasa inšpirácie zajatí 3d printed fidget spinner balík

3D printing gears is possible, sometimes even preferable! Easily learn how to make 3D printed gears that fit your needs.

morská riasa inšpirácie zajatí 3d printed fidget spinner balík

Download files and build them with your 3D printer, laser cutter, or CNC. Thingiverse is a universe of things.

7000 RPM on a 3DPrinted Gearbox Trending Topics PH

3D-printed gears made from iglidur® As already mentioned, customized plastic gears can be produced much more easily using SLS. In principle, any gear with a minimum wall thickness of 0.5 mm can be produced. The installation space of the SLS printer is the only limitation here.

Quiet Metal Gear Sulid V 1/10 scale 180mm 3D printed resin figure

3D Printing is an Additive Manufacturing (AM) technique that has revolutionized the world of manufacturing. However, manufacturing gears require special skills, making 3D printing seem sensible to produce them. 3D-printed gears are inherently weaker compared to their metal-cut, traditionally-made counterparts. So why 3D print gears then?

morská riasa inšpirácie zajatí 3d printed fidget spinner balík

Whether you need a model for prototyping, visualization, 3D printing, or laser cutting, we've got you covered. STL Gear Generator Our free STL gear designer is designed with simplicity in mind, making it easy for anyone to create custom gears for 3D printing.

Tips on How to Increase the Accuracy of a 3D Printer

Before diving into creating functional 3D-printed gears, you should get certain things in place. These include the right design for the machine or appliance, the right materials, size, etc. The reason is, while 3D printing speeds up the gear manufacturing process, you want to ensure that the result of the 3D printed gears is durable enough for.

Velo3D Releases Protection 3D Printing White Paper with AM Analysis

For maximum learning, we suggest learning how to design them yourself. 3D printed gears are great for exercising your modeling and 3D printing skills for functional prints. A few key concepts to understand Before jumping headfirst into the process of designing gears, let us first discuss some relevant concepts.

STL file HTC VIVE COSMOS headband gear replacement. ⚙️・Design to

Step 1: Printing & Assembly Instructions for Geared Light Switch Print all parts minimum 3 perimeters all sides top & bottom, with 15% infill. I recommend 0.3mm layer thickness maximum. Any material will work as long as you can prevent warping, which would devastate this device. The wrench file is the only one that needs print supports/scaffolding.

3D Printing 102 Allen County Public Library

Print with a solid infill A solid infill uses more filament, but you get stronger, more durable gears in return. Gears go through lots of mechanical stress, and using a 100% infill ensures that there are no points of failure in the gears from hollow areas.

Artistic 3D Composition of Gears Human Head, Human Intelligence with

Download files and build them with your 3D printer, laser cutter, or CNC. Thingiverse is a universe of things.

Upgrade CR10S PRO Dual Gear Extruder, Ender 3 Extruder Blue

Intro How To 3D Print Gears Like a Boss thehardwareguy 55.4K subscribers Subscribe Subscribed 395K views 2 years ago #3dprinting #CAD #gears Kindly consider supporting me:.

3D Printed Gears How to Make Them All3DP

What advantages do 3D printer gears have? Today we will, give you pro tips on the design process, discuss the 3D printing materials, and also advise you on the best software to use. Are you ready? Gear up! Design Tips: what to watch out for when 3D printing gears Number of teeth When designing gears you have to think of their ratio.

YouTuber builds water clock using 3D printing and publishes instructions

3D-printed gears from igus® Additive manufacturing for low-wear gears, spur gears, bevel gears, sprockets and worm wheels Our 3D-printed gears are made of low-friction, maintenance-free, self-lubricating plastic printing materials that have been engineered to last up to 50 times longer than standard 3D-printing materials inside moving applications.